The Force Main Didn’t Fail Overnight

It Failed One Pressure Wave at a Time

Most force mains don’t fail because they’re old.

They fail because they’re angry.

Angry from thousands of pressure waves slamming into pipe walls day after day, mostly unseen, mostly ignored until one day the system gives up and everyone calls it “aging infrastructure.”

That’s a lie we tell ourselves to feel better.

In reality, force main failures are often engineered into existence, one transient event at a time.

The Problem Nobody Sees Until It’s Too Late

A force main’s job is simple: move wastewater from a lift station to a treatment plant. Underground. Out of sight. Out of mind.

That’s exactly why force mains are dangerous.

They experience transient pressure events — water hammer — that can travel through a pipeline at speeds approaching 4,500 feet per second, depending on pipe material. Ductile iron transmits these waves faster. PVC slows them down — but doesn’t make them harmless.

Here’s the uncomfortable truth:

Most utilities are blind to these events. FACT!

Why? Because traditional pressure monitoring samples too slowly. When you measure pressure once every few seconds, you don’t see the peaks. You don’t see the valleys. You don’t see the damage being done.

At low sampling rates, a 300+ psi spike can look like a harmless 70 psi blip. The data lies — not maliciously, just insufficiently.

High-resolution monitoring (on the order of 100+ samples per second) tells a very different story.

Energy Doesn’t Care About Your Assumptions

As systems age and populations grow, utilities often increase flow to meet demand. On paper, the pipe can “handle it.”

In reality, velocity increases — and energy increases with the square of velocity.

That means small operational changes can dramatically raise transient energy inside the pipe. Combine that with aging infrastructure, restricted flow, or poor air management, and you’ve built a fatigue machine.

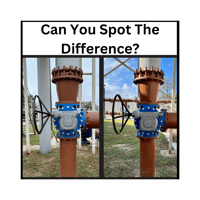

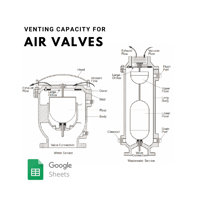

Check valves, air valves, surge devices…these aren’t accessories. They’re structural necessities. But even the best hardware is only as good as the assumptions behind it.

And assumptions fail quietly.

A Real System. A Real Failure.

In early 2022, a Florida utility agreed to deploy a “Calming the Network” study. What they didn’t say at first was that they were operating under a consent decree tied to a previous force main failure.

The goal wasn’t theory, it was proof.

By mid-2022, high-resolution pressure monitoring devices were installed on the system. The data streamed to the cloud. Algorithms analyzed patterns. Pressure behavior became visible for the first time.

Then, in January 2023, the system failed again.

A routine automatic generator exercise caused a pressure spike that led to a force main break and a spill. The difference this time? We could see exactly why it happened.

A surge analysis, calibrated with real field data showed negative pressures and transient magnitudes that exceeded the pipe’s tolerance. With surge mitigation modeled into the system, those same events disappeared on paper and in the field.

This wasn’t a mystery failure.

It was a predictable outcome of unmitigated transients.

The Most Dangerous Pipe Profile in America

Flat force mains are the most deceptively risky systems in operation.

Why? Because low static head makes it easy to drop into vacuum conditions. A pump discharge pressure of 40 psi doesn’t have much room to fall before hitting -14.7 psi — full vacuum at sea level.

When that happens, vapor pockets form. The water literally boils inside the pipe.

These voids can stretch hundreds — or thousands — of feet. When they collapse, the pipe re-pressurizes instantly, often to several hundred psi. That’s not operation. That’s abuse.

Microfractures form. Corrosion accelerates. Fatigue compounds.

And eventually, someone blames the pipe material.

What High-Resolution Monitoring Actually Buys You

This isn’t about “more data.” It’s about actionable data.

Modern high-resolution pressure monitoring doesn’t stream everything all the time. Devices sample at high frequency continuously, but only transmit summaries, unless a transient event triggers full-resolution capture.

The result?

Utilities can detect:

- Check valve slam

- Pipe breaks

- Pump performance degradation

- Blockages

- Air pocket formation

- Negative pressure events

All before customers notice — and long before a spill makes the news.

Think of it as your guardian angle for buried infrastructure.

The Hard Truth

Pipes don’t “just fail.”

Failures start as microfractures — caused by transient stress. Corrosion follows the cracks. Material becomes irrelevant at that point.

Cast iron, ductile iron, PVC…every material fails under fatigue. Might not be instantly, but overtime failure is inevitable with the right conditions.

There’s an old theory that piping fatigue failures are driven primarily by water hammer. After watching these systems up close, it’s getting harder to argue otherwise.

The Way Forward

If utilities don’t want to run a full surge analysis on every force main, fine. Start with high-resolution monitoring at the lift station. One week of data is often enough to reveal whether a system is at risk.

Indefinite monitoring is better.

Because the most expensive force main failure isn’t the one that breaks the pipe.

It’s the one you could have seen coming.

// This original topic “Force Main Transients”, was presented on at the 2024 Florida Water Resources Conference (FWRC).